|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

| |

|

The Marimex Industries ViscoScope Systems measure the dynamic viscosity of liquids continually and precisely in-line. The ViscoScope system consists of a rugged sensor and associated electronics, which has been designed for process environments. The sensor has a rugged design and high resistance against foreign influences and can be applied in many industries including chemical, petrochemical, pharmaceutical and food industries. |

|

|

|

|

Viscoscope System

The ViscoScope system consists of a rugged sensor and an associated electronic, which has been designed for process environments. With its rugged design and high resistance against foreign influences, the sensor can be applied in many industries including chemical, petrochemical, pharmaceutical and food industry.

The ViscoScope system measures the dynamic viscosity directly in the process.

Technical Specifications Technical Specifications

|

|

|

|

|

ViscoScope VA-300L

The ViscoScope VA-300L sensor is designed for the measurement of low viscosities. The range which can be covered by the Model VA-300L is:

Range: 0.10 to 2,500.00 mPa.s x gr/cm3

Typically the VA-300L sensor is calibrated for a three decade range but is capable to cover more than 4 decades of viscosity measurement.

Technical Specifications Technical Specifications

|

|

|

|

|

ViscoScope VA-300M

The ViscoScope sensor VA-300M is designed for the measurement of medium viscosities. The range which can be covered by the Model VA300M is:

Range: 1.0 to 25,000.0 mPa.s x gr/cm3

Typically the VA-300M sensor is calibrated for a three decade range but is capable to cover more than 4 decades of viscosity measurement.

Technical Specifications Technical Specifications

|

|

|

|

|

ViscoScope VA-300H

The ViscoScope VA-300H sensor is designed for the measurement of high viscosities. The range which can be covered by the Model VA-300H is:

Range: 10 to 250,000 mPa.s x gr/cm3

Typically the VA-300H sensor is calibrated for a three decade range but is capable to cover more than 4 decades of viscosity measurement.

Technical Specifications Technical Specifications

|

|

|

|

|

ViscoScope VA-300X

The ViscoScope VA-300X sensor is designed for the measurement of very high viscosities. The range which can be covered by the Model VA-300X is:

Range: 1,000 to 2,500,000 mPa.s x gr/cm3

Typically the VA-300X sensor is calibrated for a three decade range but is capable to cover more than 4 decades of viscosity measurement.

Technical Specifications Technical Specifications

|

|

|

|

|

ViscoScope VA-300S

The ViscoScope VA-300S sensor a custom designed sensor, which is specifically constructed to measurement requirements a particular customer may have. This sensor is available for temperatures up to 1500degC.

Range: 1.0 to 2,500,000 mPa.s x gr/cm3

Typically the VA-300S sensor is calibrated for a three decade range but is capable to cover more than 4 decades of viscosity measurement.

Technical Specifications Technical Specifications

|

|

|

|

|

ViscoScope VS-4450

The ViscoScope electronic connects to to any ViscoScope sensor.

The ViscoScope electronic VS-4450 is a new development, which utilises the latest integrated technology available. It is a forward looking development, which has been designed in such a way, that future requirements can easily be added and integrated. Especially in conjunction with our ViscoScope VL-300S sensor, unique customer demands can be accommodated.

Safety features, which are part of the integrated system, make applications possible, which could previously not be handled. The integrated safety features also make it possible to cover all ranges and temperature classes with one basic sensor design.

Technical Specifications Technical Specifications

|

|

|

|

|

ViscoScope VS-B450

The ViscoScope transmitter VS-B450 connects to anyE ViscoScope sensor.

The ViscoScope transmitter VS-B550 is a new development and utilizes the latest integrated technology available. It is a forward looking development, which has been designed in such a way, that future developments can easily be added and integrated. Especially in conjunction with our ViscoScope VL-300S sensor, unique customer requirements can now be accommodated.

Safety features, which are part of the integrated system, make applications possible, which could previously not be handled. The integrated safety features also make it possible to cover all ranges and temperature classes with one basic sensor design.

Technical Specifications Technical Specifications

|

|

|

|

|

ViscoView

The ViscoView® data collection software connects via Modbus protocol and RS232 or RS485 serial interface to the ViscoScope transmitter series. ViscoView® works with a PC under Windows® 98 / NT / 2000 and XP.

Technical Specifications Technical Specifications

|

| |

|

|

|

| |

|

|

|

|

|

|

|

| PCR Process Control Rheometer |

| |

The HAAKE PCR's patented bypass design makes it possible to measure the viscosity at low shear rates without compromising residence time, this results in a much higher sensitivity when comparing different molecular weight materials.

The die exit pressure control feature allows the HAAKE PCR to operate at pre defined pressures ensuring operation in the linear region of the transducers and preventing degasing of intrigents with high gas pressure. This also allows covering a wide melt index range and product transitions with a single die, eliminating costly and time consuming die changes common to other systems.

|

|

|

| Materials |

|

|

|

Polypropylene (PP) |

|

|

|

Polyethylene (LDPE/HDPE/LLDPE) |

|

|

|

Polyester (PET) |

|

|

|

Ethylen Vinyl Acetate (EVA) |

|

|

|

Polymethyl-methacrylate (PMMA) |

|

|

|

Polystyrene (PS) |

|

|

|

Polyamide / Nylon (PA) |

|

Polycarbonate (PC) |

|

|

|

|

Stress : 5 to 250kPa

ASTM D-1238 loads : 0.5 to 25kg

Shear Rate : 0.03 to 4000 1/sec

Viscosity : 2 to 240,000 Pa.s , 20 to 2,400,000 poise

Melt Flow Index : 0.02 to 3000

Temperature : 50° to 350°C (400°C option)

Pumps Rheometer : 0.584 to 1.752 cc/rev

Max. Speed : 60rpm

Pressure Transducers : 100 to 350 bar (1500 to 5000psi)

Slit Dies Height : 0.03 to 0.2cm

Length x Width : 4 to 8cm x 2.25 to 1.2cm

Power : 220VAC, 50/60Hz, 30A, single phase

Weight Rheometer : 115kg (250 lb.)

Electronics : 43kg (95 lb.) |

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

|

|

Product Catalog

|

|

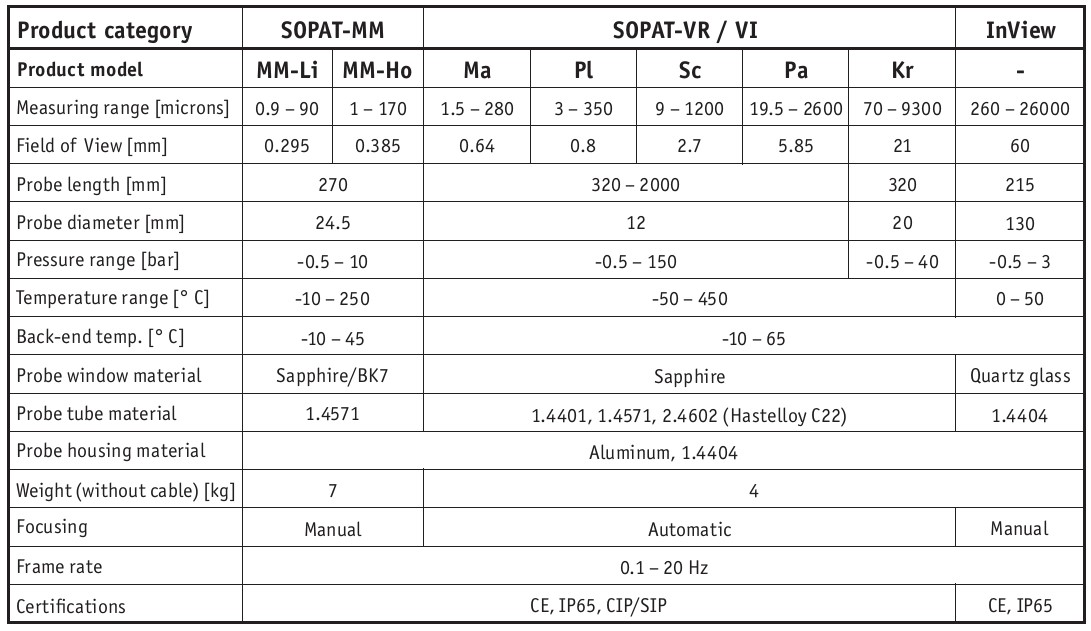

SOPAT-Smart Online Particle Analysis Technology

Automated Image Analysis of Droplets, Bubbles and Particles

SOPAT offers a time-saving, automated technique for image analysis. Our privately developed algorithm identifies and recognizes various particles regardless of concentration, including droplets, grains and cells, of course quickly and efficiently.

The results of the measurement analysis can be obtained at a moment’s notice, ready for your process control system.

|

|

|

| |

|

|

|

| |

|

|

| |

|

|

|

|

|

|

|

|

|

SOPAT-VI-Industry Probe

|

| Particle Size range from 2um to 1cm |

Particles are a significant component of various processes and products. Not only is it relevant to study them in a laboratory setting, but the knowledge that can be gained serves to optimize even the most complicated of industrial applications. Obtaining this information, of course, can be a very laborious and challenging process. Our technology measures the size and distribution of particles in-situ and in real-time, even at high concentrations.

The SOPAT-VI Probe enables online process monitoring of particle sizes and characteristics. This enables quick process control response during production and is able to fully auomate quality control.

|

|

|

SOPAT-VR-HP-High Pressure Probe

|

The technology offered by SOPAT can also be applied under extreme process conditions: high pressures, temperatures and corrosive environments are no problem. Results are then delivered accurately and up to speed with your process. Measurements and data are presented in an intuitive manner and can be analyzed immediately.

|

- Operating pressure: 0.5 to 320 bar

- Operating temperature: -20 to 180°C (-40 to 450°C with cooling system)

SOPAT-VR-HS-High Speed Probe

- Product model for high-speed systems

- 4 Megapixels at up to 2,500 images per second

- Observe the finest details of your process with the highest and most accurate precision

SOPAT-VR-Laboratory Probe

|  |

| Particle Size range from 2um to 1cm |

|

Particles are a significant component of various processes and products. Not only is it relevant to study them in a laboratory setting, but the knowledge that can be gained serves to optimize even the most complicated of industrial applications. Obtaining this information, of course, can be a very laborious and challenging process. Our technology measures the size and distribution of particles in-situ and in real-time, even at high concentrations.

The SOPAT Drop Research Probe streamlines experimental laboratory work, confirms the reproducibility of results and opens the door of possibilities for monitoring process control in real-time.

The SOPAT-Probe is also offered in a variety of models to accommodate extreme operating conditions (SOPAT-HP) and processes the require extremely high frame rates (SOPAT-HS).

SOPAT-MM-Microscope Probe

|  |

| Particle Size range from 0.9μm to 200μm |

|

SOPAT is specialized in the analysis of particulate systems. Our team develops and markets an innovative particle measurement technology for real-time analysis of multi-phase systems. Particles, such as droplets, grains, cells or bubbles, are measured with high precision in running processes. The developed technology consists of a photo-optical sensor probe with integrated intelligent image analysis.

SOPAT-InView-Camera

|  |

Particle Size range from 30 μm to 10cm

The developed technology consists of a photo-optical sensor probe with integrated intelligent image analysis. SOPAT is specialized in the precise analysis of particles in ongoing chemical processes. Our expertise spans from the hardware systems required to capture images within your process, the machine learning required to analyze their contentand the process control needed to empower industrial processes. SOPAT offers measurement services onsite ,at industrial plants and research facilities or provide you with an overview of the potential for your application.

|

|

|

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| Innovative by Design |

|

|

Mageleka’s flagship instrument is the MagnoMeter XRS™, a powerful and versatile next-generation benchtop low-field NMR relaxometer that provides fast, accurate, particle characterization and surface analysis of dispersions. The MagnoMeter XRS™ provides unmatched functionality and unparalleled analysis and performance, at any stage of the formulation or manufacture process, across any industry.

|

| Separate magnet/probe assembly pod |

|

|

Easily exchangeable for different nuclei and/or higher field strength magnets

Highly customizable pulse sequencing Phase cycling, composite pulses, two channel RF, and 1D, 2D, and 3D shaped gradients Remote operation For use in controlled, hazardous, or radioactive environments.

|

| Uses regular length NMR tubes |

|

|

Four diameters available, from 2mm (highest resolution) to 10mm (lowest resolution)

|

| Highly customizable pulse sequencing |

|

|

Phase cycling, composite pulses, two channel RF, and 1D, 2D, and 3D shaped gradients

|

| Simple and intuitive software |

|

|

Easy to use and upgrade PC software and a dedicated dual core ARM9 processor running Debian

|

| Remote operation |

|

|

For use in controlled, hazardous, or radioactive environments.

|

| All industry relevant concentrations |

|

|

Measure materials or products at any stage of the formulation and manufacturing process

|

| Separate magnet/sample probe assembly |

|

|

The magnet/sample probe assembly called a MagnoPod™ is a separate, temperature-controlled unit. This practical feature allows the MagnoMeter XRS™ to be operated remotely. Each unit can accommodate multiple MagnoPods™, which adds flexibility and extends the scope of any application. The MagnoMeter XRS™ is ideal for use in controlled or hazardous environments, and can be integrated into production equipment. The small footprint saves space in any lab, and the low weight makes it easily portable.

|

| By direct digital synthesis (DDS) |

|

|

At the heart of the MagnoMeter XRS™ is state of the art NMR technology (patent pending). It features Direct Digital Synthesis, which incorporates a software defined radio device. Radio frequency generation and detection is done digitally there are no analogue multiplexing steps in detecting the NMR signal.

This next generation technology provides the MagnoMeter XRS™ with exceptional resolution of complex solid-liquid and liquid-liquid formulations at any concentration and at significantly faster speeds than the competition.

|

| MagnoSoft™: simple and intuitive software |

|

|

Measurements using the MagnoMeter XRS™ are based on its simple and intuitive MagnoSoft™ program, and operation requires minimal training and expertise. The MagnoSoft™ program can control multiple MagnoPods™ from one central control unit, which adds incredible flexibility and eliminates the need to purchase multiple instruments.

|

| Highly customizable pulse sequencing |

|

|

The MagnoMeter XRS™ features phase cycling, composite pulses, and two-channel radio frequency and 3D shaped gradients, all customizable by the pulse programming interface of the MagnoSoft™ program. This makes possible 1D, 2D, and 3D imaging, robust self-diffusion measurement (10-9 to 10-13 m2s-1), droplet sizing analysis, polymer characterization in solution and melts, and more.

|

| Uses regular length NMR tubes |

|

|

With the MagnoMeter XRS™ there is no need to change the way you work or the type of NMR tube you use. It is challenging to fill a narrow NMR tube with a highly viscous fluid, so larger-diameter tubes are needed. Conversely, when sample volume is very low, or higher resolution is needed, a narrow diameter tube is ideal. Accordingly, the MagnoPod™ can accommodate four different diameter NMR tubes: 2 mm (highest resolution), 4 mm (standard resolution), 8 mm (lower resolution) and 10 mm (lowest resolution).

| |

| |

|

|

|

| |

|

|

|

| |

|

|

|

|

|

|