|

|

|

|

|

|

| |

|

|

|

| |

|

|

|

|

|

|

|

|

| |

|

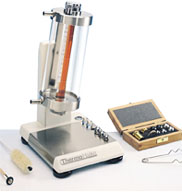

The Falling Ball Viscometer

type C measures accurately the viscosity of transparent Newtonian

liquids and gases. It meets the requirements of the German DIN

53015 as well as ISO 12058 standard and it is accepted as an

official reference instrument.

Its measuring accuracy when backed up by the precise temperature

control of a ThermoHaake circulator is not surpassed by any

other type of viscometer. |

|

|

| The Falling Ball Viscosimeter

is mainly used for low viscous substances such as used in: |

|

|

|

Chemical industry (polymer solutions, solvents, inks) |

|

|

|

Pharmaceutical industry (raw materials, glycerine) |

|

|

|

Food industry (gelatin, sugar solutions) |

|

|

|

Mineral oil industry (oils, liquid hydrocarbons) |

| |

|

|

| |

|

|

High accuracy through improved visibility of falling ball |

|

|

|

Minimized test time due to accurate return run of the ball |

|

|

|

Reduced cost of ownership through increased life

time of falling tube |

|

|

|

Extended re-calibration periods through improved bearing support |

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

|

|

|

|

HAAKE Viscotester 3 Rotational Viscometer

Perform Viscosity measurements with easy! The self explaining Thermo Scientific HAAKE Viscotester 3 rotational viscometer ensures quick, reliable tests for QC applications

Everything about this instrument is designed for ease of use its shape, weight, display, and more. Use it as a handheld viscometer or on a lab stand. Color coding ensures measuring geometries match the analysis, the display is readable in any lighting, and the viscometer remembers the reference point measurement for you. All that comes in a ready-to-go carrying case. Its so easy to use its just sheer genius.

Designed for simplicity The HAAKE Viscotester 3 rotational viscometer is built for ease of use to get you quickly to the right viscosity measurements:

Self-explaining handling

Smart alignment given by design and visualized by an electronic level

Quick coupling of measuring geometries for fast and easy adaptation

Color coded geometries and a geometry range indicator ensure correct rotor selection every time

Adaptable display brightness ensures ideal readability in any environment

Battery and power supply options allow the viscometer to be run anywhere

Memory assist functionality allows you to quickly and easily compare measured viscosities with the reference point

Selectable viscosity units (mPa s or dPa s)

Compatibility with previous viscometer models

Recommended for: your entire process, from accepting the delivery of goods, to sampling during production and quality control (QC).

Printing inks, paints, inks and other coatings

Shampoos, creams, lotions, and similar personal care products

Oil, greases, pastes and similar substances

Sauces, thickeners, and similar food products

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

|

|

|

|

| The Thermo Scientific* HAAKE Viscotester E, D and C units can be used for tests and comparative viscosity measurements for quality control according to recognized standards.

The HAAKE Viscotester E, D and C are rotational viscometers that measure the resistance of a test substance against a pre-set speed. The resulting torque or resistance measures the viscosity of the fluid. The higher the torque, the higher the viscosity. |

|

|

| Common features of the HAAKE Viscotester E, D and C |

|

|

|

Digital display of viscosity, % torque, speed, spindle, upper viscosity limit, |

|

|

| |

temperature (optional), in selectable units |

|

|

|

Integrated automatic diagnostic functionality |

|

|

|

Visual and acoustic signals at critical measuring conditions |

|

|

|

Easy viscosity and temperature (optional) calibrations |

|

|

|

10 user interface languages |

|

|

|

Two year warranty |

| |

|

| Compliance: The HAAKE Viscotester E, D and C meet the following standards: |

|

|

BS 6075, 5350

ISO 2555, 1652

ASTM 115, 789, 1076, 1084, 1286, 1417, 1439, 1638, 1824, 2196,2336, 2364, 2393, 2556, 2669, 2849, 2983, 2994, 3232, 3236, 3716 |

| |

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

|

|

Eng Catalog

Kor Catalog

|

|

| The Schleibinger Viskomat NT is a versatile rotational viscometer for determining the workability of fine-grained building materials such as cement paste, mortar, fine concrete, plaster etc. with a maximum particle size of 2mm. |

|

|

| The data available includes: |

|

|

|

flow curves and rheological parameters |

|

|

|

temperature dependent workability properties |

|

|

|

stiffening behaviour as a function of time and stirring speed |

|

|

|

effects of concrete admixtures and mineral blending agents on workability |

|

|

| Features |

|

|

|

robust apparatus for industrial environments �� quality control, research and development |

|

|

|

informative, easy to use test procedures |

|

|

|

automatic running of predefined test procedures which can be either standardised or tailored to your own requirements |

|

|

|

inhomogeneous materials measurable with particles up to 2 mm using special paddles to avoid separation |

| |

|

|

|

|

Voltage, Frequency : 110...230/50 - 60 Hz

Size Viskomat : 300x670x50mm (wxdxh)

Size Control Unit : 190x450x350mm (wxdxh)

Torque :

0-��250Nmm

Speed : ��0,001-��400 rpm

Sample Volume : 370 ml

Weight : 20 ca. kg |

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

|

|

Eng Catalog

Kor Catalog

|

|

The Schleibinger BT2 is a compact rheometer for fresh concrete. In contrast to the spread table the concrete is tested at various loads. Therefore you can determine a relative yield stress and a relative viscosity. The construction avoids structural breakdown and segregation during measuring. The BT2 is small, power independent and easy to use.

A sample of test material is placed in the sample container. The BT2 is fixed into the middle of the sample container and turned one revolution by hand. The internal software measures the data by monitoring the momentum on the three probes and the angular velocity. On completion of the measurement the readings can be wirelessly transferred and displayed on an external Palmtop.

As with most rheometers the shear stress is measured at various speeds when a probe is rotating in the container. With the BT2 you will get three speeds at the same time. So one revolution is enough. You will never measure in the same place twice.

The system is driven by hand, and all the electronics are power independent. The ideal instrument specially designed for the building site. |

| |

|

|

|

|

Container diameter : 50 cm

Height of the shaft : 130 mm

Specimen volume : 19.6 Litre

Length measurement arm, : 43 cm

Length probes : 90 mm

Measurement range torque : 0-3 Nm

Measurement range speed : 0-4 m/s

Resolution angle : 1000 / 2 pi

Display in the external device : Graphical display Palmtop 160x160 points

Handling : 2 buttons + external Palmtop (included)

Interface : IRDA ��

Power supply : 4 A cells C size

Weight wo container : ca. 6.9 kg |

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

|

|

Kor Catalog

|

|

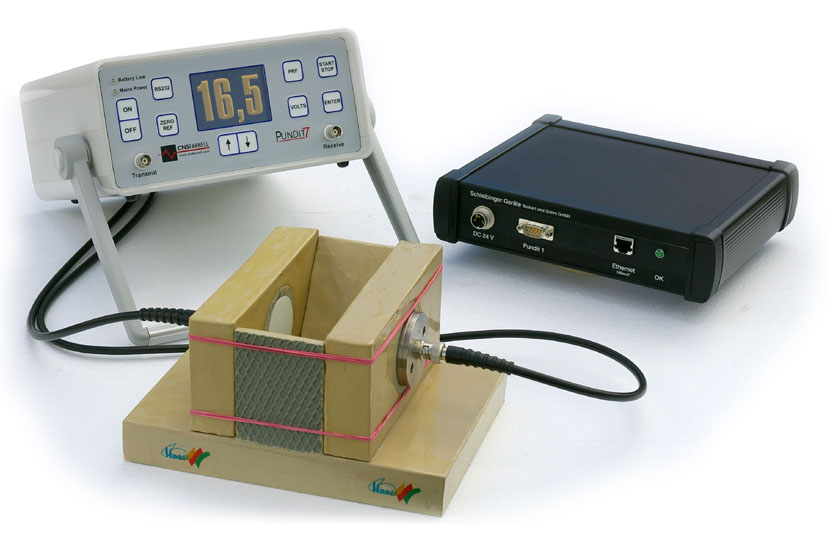

Measuring the Early Setting and Hardening with Schleibinger Ultrasonic Datalogger.

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

|

|

|

|

Bending Beam Rheometer (BBR),

Rolling Thin Film Oven (RTFO),

Pressure Aging Vessel (PAV) and

Dynamic Stress Rheometer (DSR)

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

|

|

|