|

|

|

|

|

|

| |

|

| |

|

|

|

|

|

|

|

|

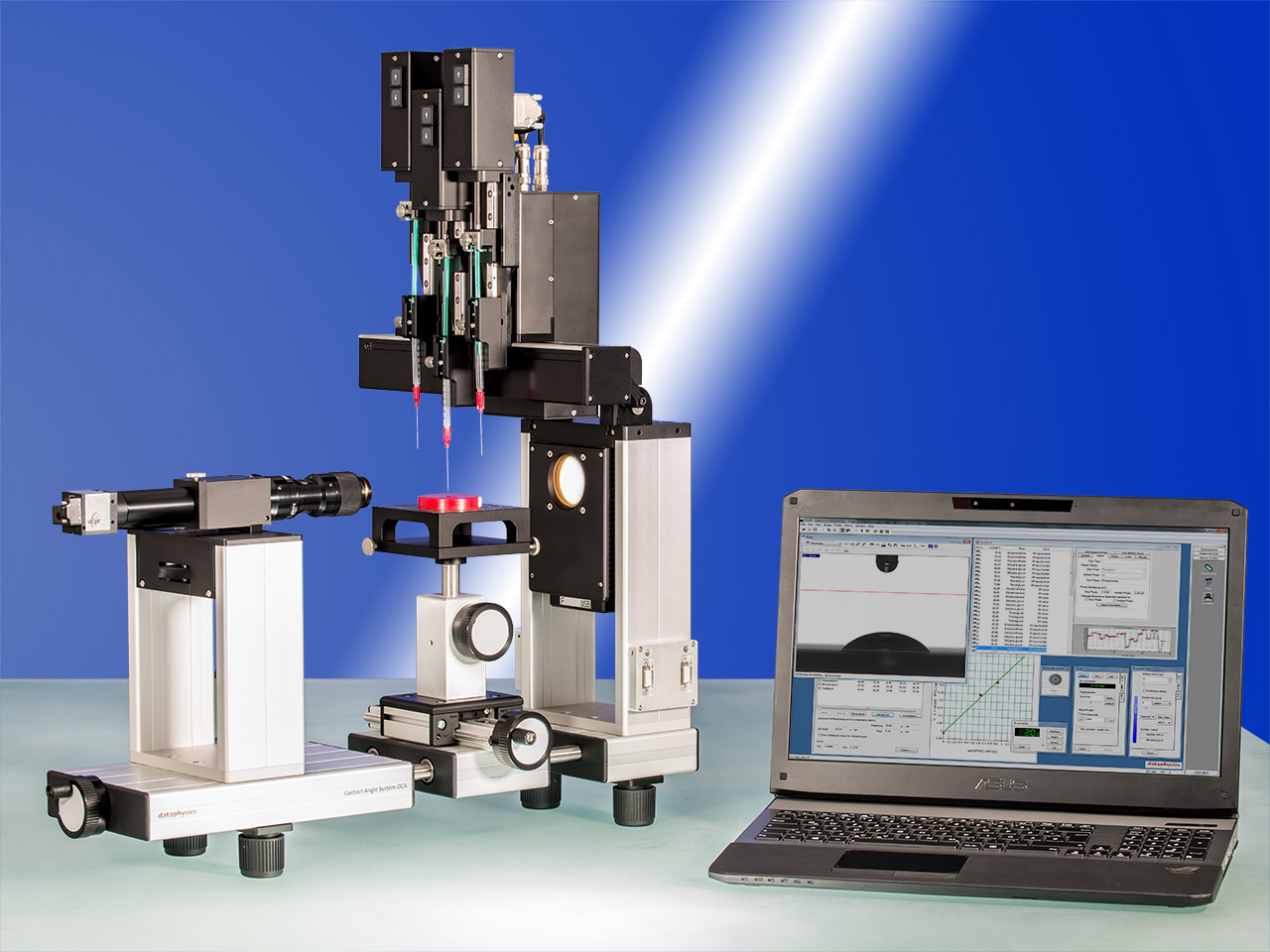

OCA

15EC

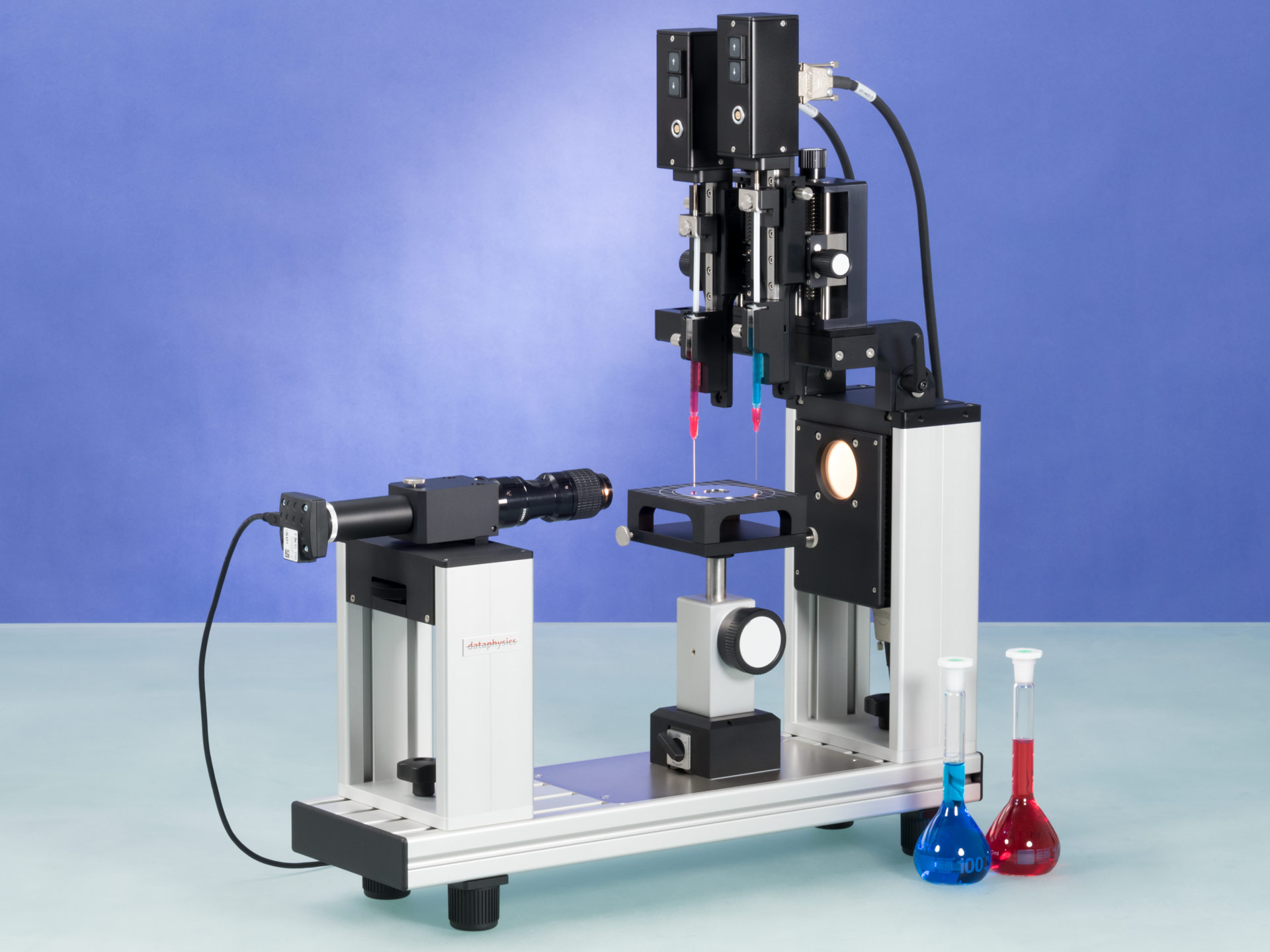

The OCA 15EC is the entry level measuring device for professional contact angle measurements and drop shape analysis.

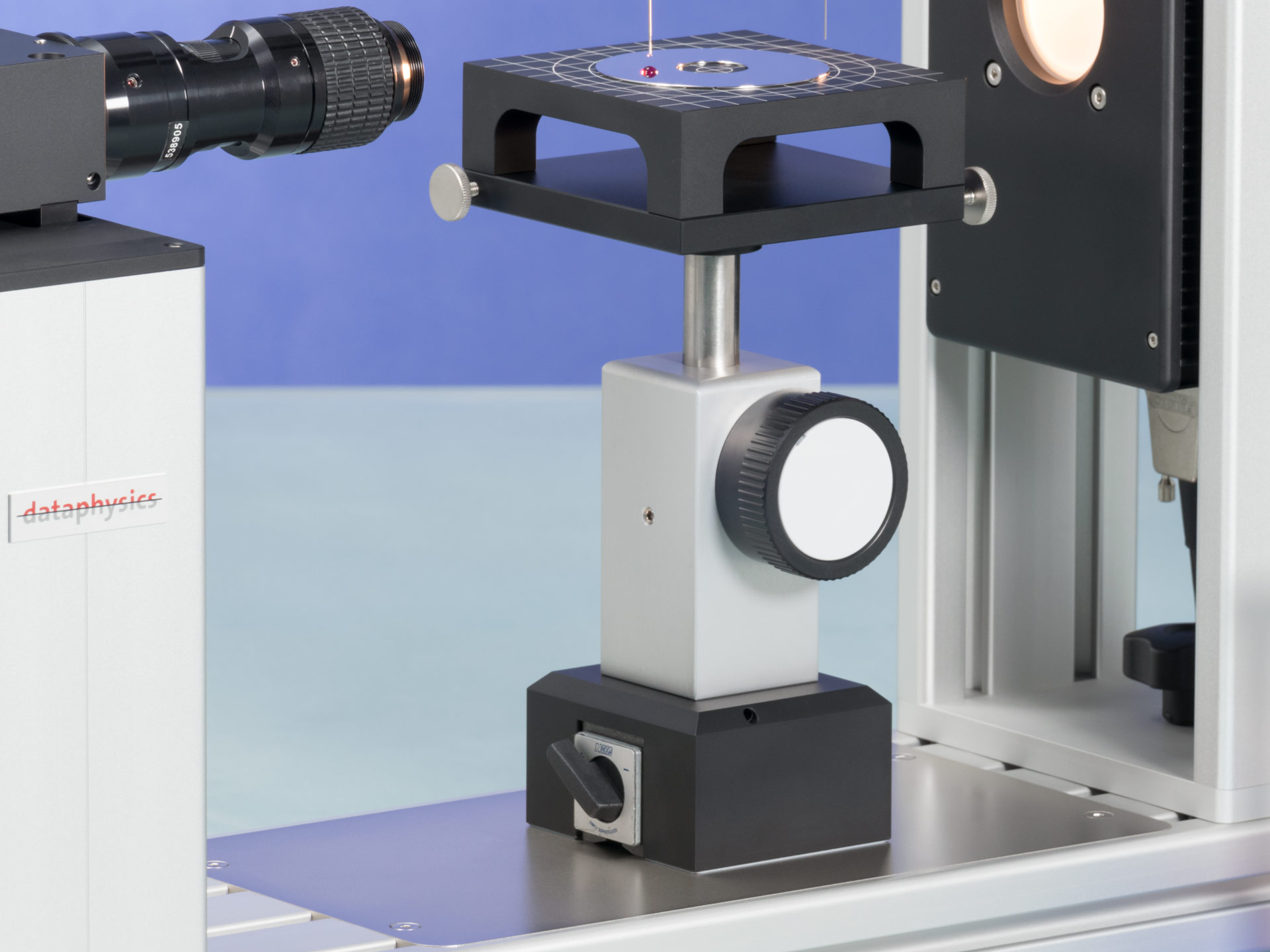

The sample table of the OCA 15EC can slide freely in X- and Y-direction and is locked into position with its switchable magnetic base. In Z-direction the sample table is adjustable using precision mechanics with a hand wheel.

The fast 6-fold zoom lens with manual focus and adjustable observation angle in combination with the USB camera ensures pin-sharp drop images and facilitates the effortless analysis with the SCA software.

With a single direct dosing system SD-DM or a double direct dosing system DD-DM liquids can be positioned and dosed with one or two electronic syringe modules ESr-N, respectively.

Direct tubeless dosing of the syringe content and the ability to use cost-saving disposable syringes and needles allow for short preparation times and minimal cleaning efforts.

Even though the OCA 15EC is a high precision measuring device designed for laboratory use, it is highly mobile and can effortlessly be taken apart with two star grip screws and be stored securely in a transport case.

For a fast and convenient access to the surface and interfacial measurements two pre-configured packages are available. These include all necessary components to get started immediately.

The OCA 15EC Package 1 consists of the base unit, a single direct dosing system SD-DM, one electronic syringe unit ESr-N and the software module SCA 20.

The OCA 15EC Package 2 consists of the base unit, a double direct dosing system DD-DM, two electronic syringe units ESr-N and the software module SCA 20.

|

|

|

|

Main features:

|

|

|

sample table horizontally movable (magnetic slide system) and adjustable vertically with precision mechanics

|

|

|

|

|

high performance 6-times zoom lens

|

|

|

|

|

integrated continuous fine focus, and adjustable observation angle

|

|

|

|

|

LED-lighting with manual and software controlled intensity including automatic temperature drift compensation

|

|

|

|

|

video measuring system with USB camera

|

|

|

|

|

Single

direct dosing system, SD-DM, for use with standard and disposable

syringes and needles.

|

|

|

|

|

|

Software:

|

|

|

SCA 20 - contact angle

|

|

|

|

|

SCA 21 - surface energy

|

|

|

|

|

SCA 22 - surface and interfacial tension

|

|

|

|

|

SCA 23 - liquid bridge analysis

|

|

|

SCA 26 - oscillation / relaxation

|

|

|

|

|

| |

|

|

|

| |

|

|

|

|

|

|

|

|

OCA

15LJ

The OCA 15LJ is a special variant of the OCA 15EC that is designed to support the DataPhysics Instruments Liquid Jet systems like the Double Liquid Jet system DLJ. With the high-performance camera with USB 3.0 interface and its higher resolution multiple drops fit into the frame and can be analysed simultaneously.

The additional connecting sockets for accessories/extensions on the side of the illumination housing enable a mounting of up to four syringe modules. Hence, multiple drops can be simultaneously dosed and analysed for a surface energy determination in one-click.

|

|

|

|

Main features:

|

|

|

sample table horizontally movable (magnetic slide system) and adjustable vertically with precision mechanics

|

|

|

|

|

high performance 6-times zoom lens

|

|

|

|

|

integrated continuous fine focus, and adjustable observation angle

|

|

|

|

|

LED-lighting with manual and software controlled intensity including automatic temperature drift compensation

|

|

|

|

|

video measuring system with USB camera

|

|

|

|

|

Single

direct dosing system, SD-DM, for use with standard and disposable

syringes and needles.

|

|

|

|

|

|

Software:

|

|

|

SCA 20 - contact angle

|

|

|

|

|

SCA 21 - surface energy

|

|

|

|

|

SCA 22 - surface and interfacial tension

|

|

|

|

|

SCA 23 - liquid bridge analysis

|

|

|

SCA 26 - oscillation / relaxation

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

OCA

25

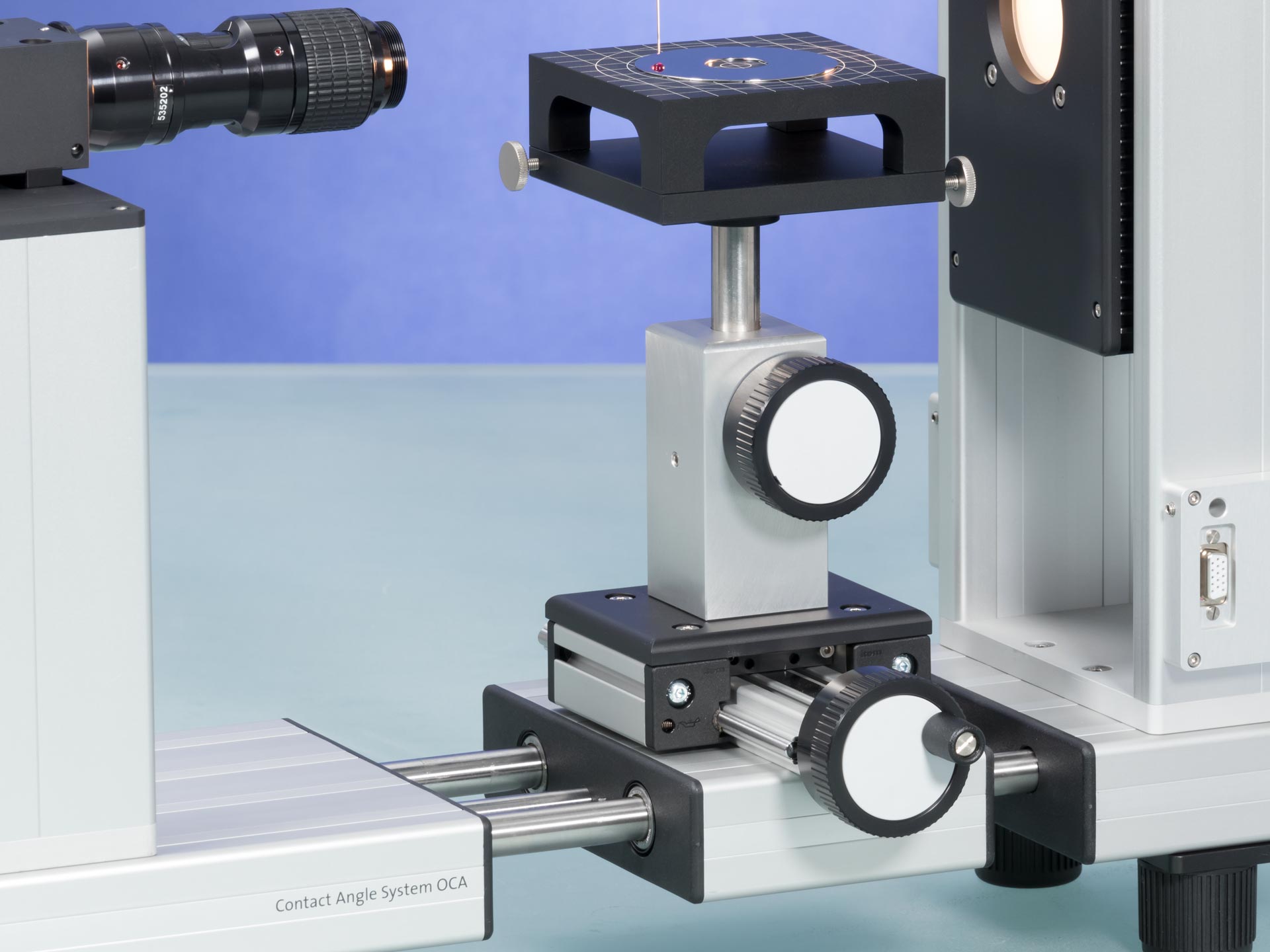

The OCA 25 is the all-purpose measuring device for contact angle measurements and drop shape analysis.

The sample table of the OCA 25 is adjustable along all three directions in space via precision axes with hand wheels. Hence, a fast and exact manual positioning of the sample is always guaranteed, even when using high-performance temperature chambers like the electrical temperature control unit TEC 700.

Analysis of even the fastest processes is possible recording up to 2450 frames/s using the 6-fold zoom lens and the high-performance camera with USB 3.0 interface. Hence, contact angles on adsorbing surfaces like tissues or powders can be measured reliably.

For dosing liquids the manual single and double direct dosing systems SD-DM and DD-DM can be used as well as the electronic multiple direct dosing systems DDE/x. The latter are able to electronically position one to four electronic syringe modules ESr-N.

Furthermore, a nanolitre dosing system can be used to generate extra small liquid drops. Even these are no challenge for the OCA 25 due to its high resolution optics.

|

|

|

|

Main features:

|

|

|

sample

table adjustable in all three axis with precision mechanics

|

|

|

|

|

high

performance 6-times zoom lens

|

|

|

|

|

integrated

continuous fine focus, and adjustable observation angle

|

|

|

|

|

video measuring system with USB

3.0 camera (max. 1220 frames/s), high-speed camera easily upgradable

(up to 3000 frames/s)

|

|

|

|

|

LED-lighting

with manual and software controlled intensity including automatic

temperature drift compensation |

|

|

|

|

|

Software:

|

|

|

SCA 20 - contact angle

|

|

|

|

|

SCA 21 - surface energy

|

|

|

|

|

SCA 22 - surface and interfacial tension

|

|

|

|

|

SCA 23 - liquid bridge analysis

|

|

|

SCA 26 - oscillation / relaxation

|

|

|

SCA 27 - topview contact angle

|

|

|

| |

|

|

|

| |

|

|

|

|

|

|

|

|

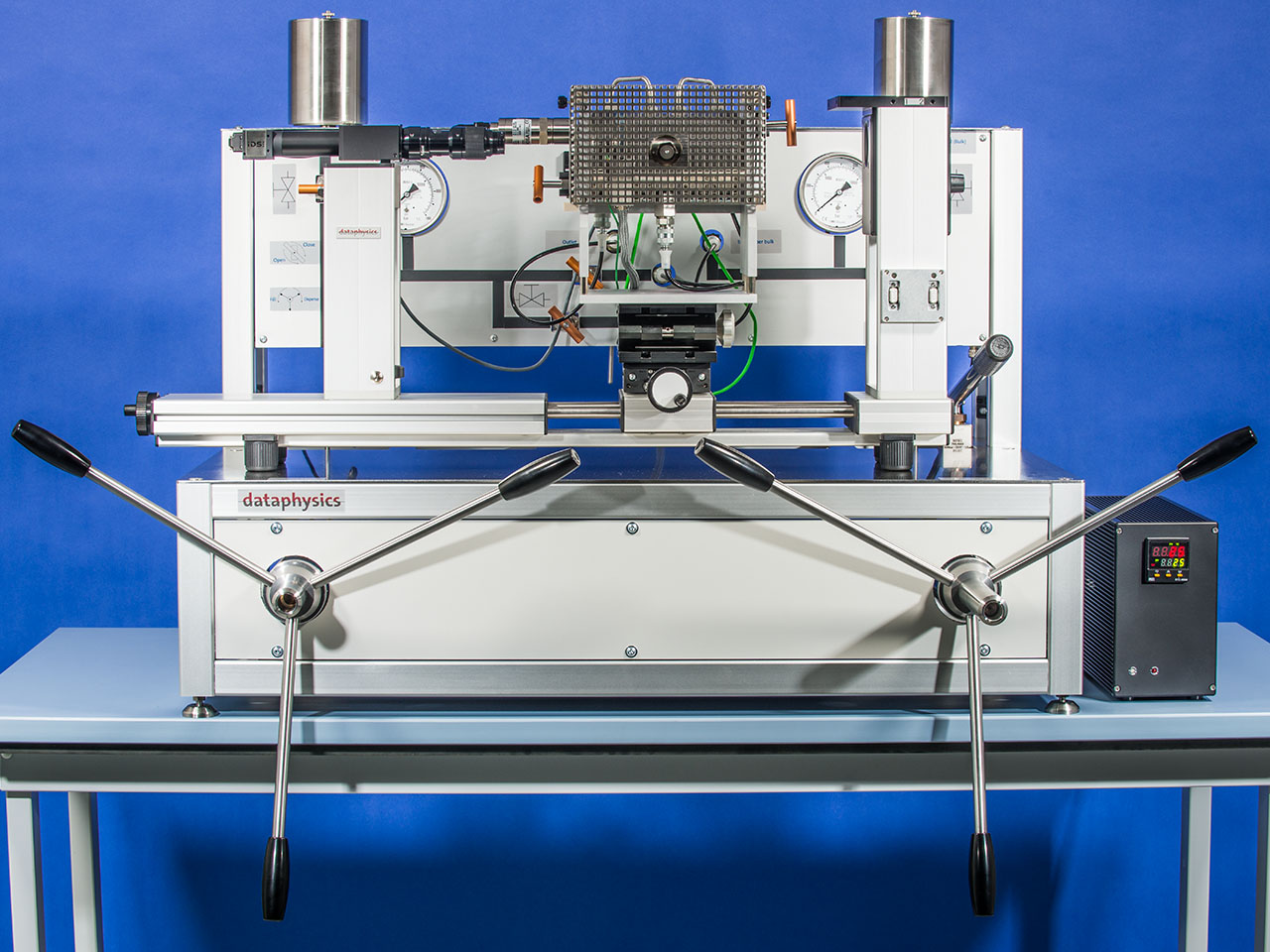

OCA 25-PMC 750

The OCA 25-PMC 750 with its high pressure measuring chamber provides the opportunity to measure interfacial tensions and contact angles at pressures of up to 750 bar and under high temperature conditions of up to 200C.

|

|

|

|

Main features:

|

|

|

high pressure chamber with optical sapphire glass

|

|

|

|

|

high pressure unit for generation and control of bulk liquid pressure and drop liquid pressure

|

|

|

|

|

temperature controller for

control of chamber temperature

|

|

|

|

|

removable

magnetic positioning system for solid samples

|

|

|

|

|

a

set of needles with different diameters for various interfacial tension

ranges

|

|

|

|

|

high performance 6-times zoom lens

|

|

|

|

|

|

|

integrated continuous fine focus, and adjustable observation angle |

|

|

|

|

|

|

video measuring system with high-performance camera using USB 3.0 interface |

|

|

|

|

|

|

LED-lighting with manual and software controlled intensity including automatic temperature drift compensation |

|

|

| |

|

|

|

| |

|

|

|

|

|

|

|

|

OCA 25 special models

The universal device platform opens the way to special models of the OCA 25, which satisfy even highest customer expectations and cope with the most challenging measuring environments.

|

|

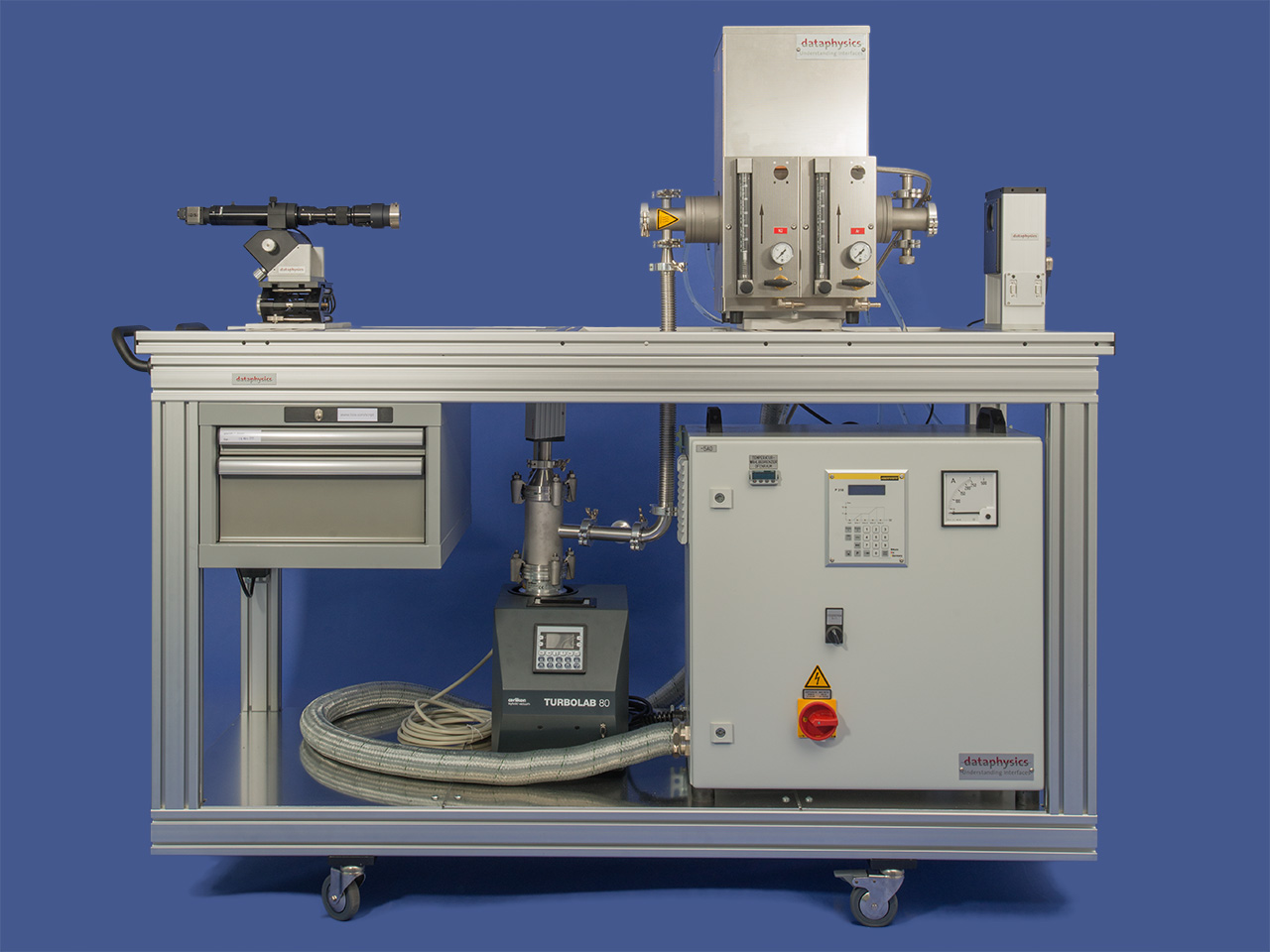

OCA 25-HTV 1800

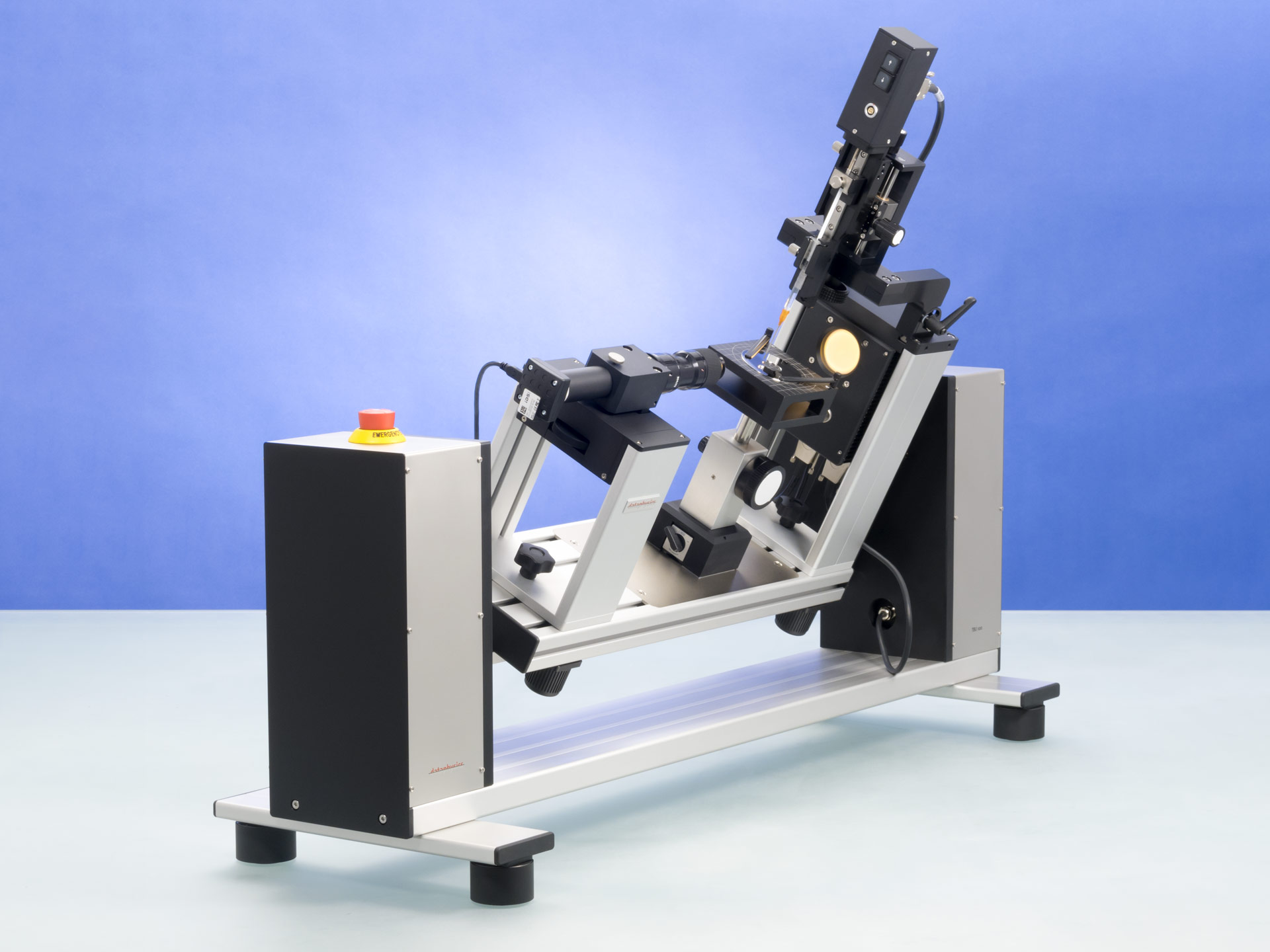

The high temperature measuring system OCA 25-HTV 1800 is capable of measuring contact angles at high temperatures of up to 1800 C and under vacuum down to 10-5 mbar or under inert gas atmosphere, respectively.

|

|

|

|

Main features:

|

|

|

high

temperature furnace up to 1800C

|

|

|

|

|

vacuum tight flanges with connectors to an optional turbomolecular pump (flanges require a water counter cooling)

|

|

|

|

|

inlets and gas supply system for

Ar and N2

|

|

|

|

|

high

power supply and control electronics

|

|

|

|

|

high performance 6-times zoom lens with zoom extender

|

|

|

|

|

integrated continuous fine focus, and adjustable observation angle

|

|

|

|

|

|

|

|

|

video measuring system with high-performance camera using USB 3.0 interface |

|

|

|

|

|

|

LED-lighting with manual and software controlled intensity including automatic temperature drift compensation |

|

|

| |

|

|

|

| |

|

|

|

|

|

|

|

|

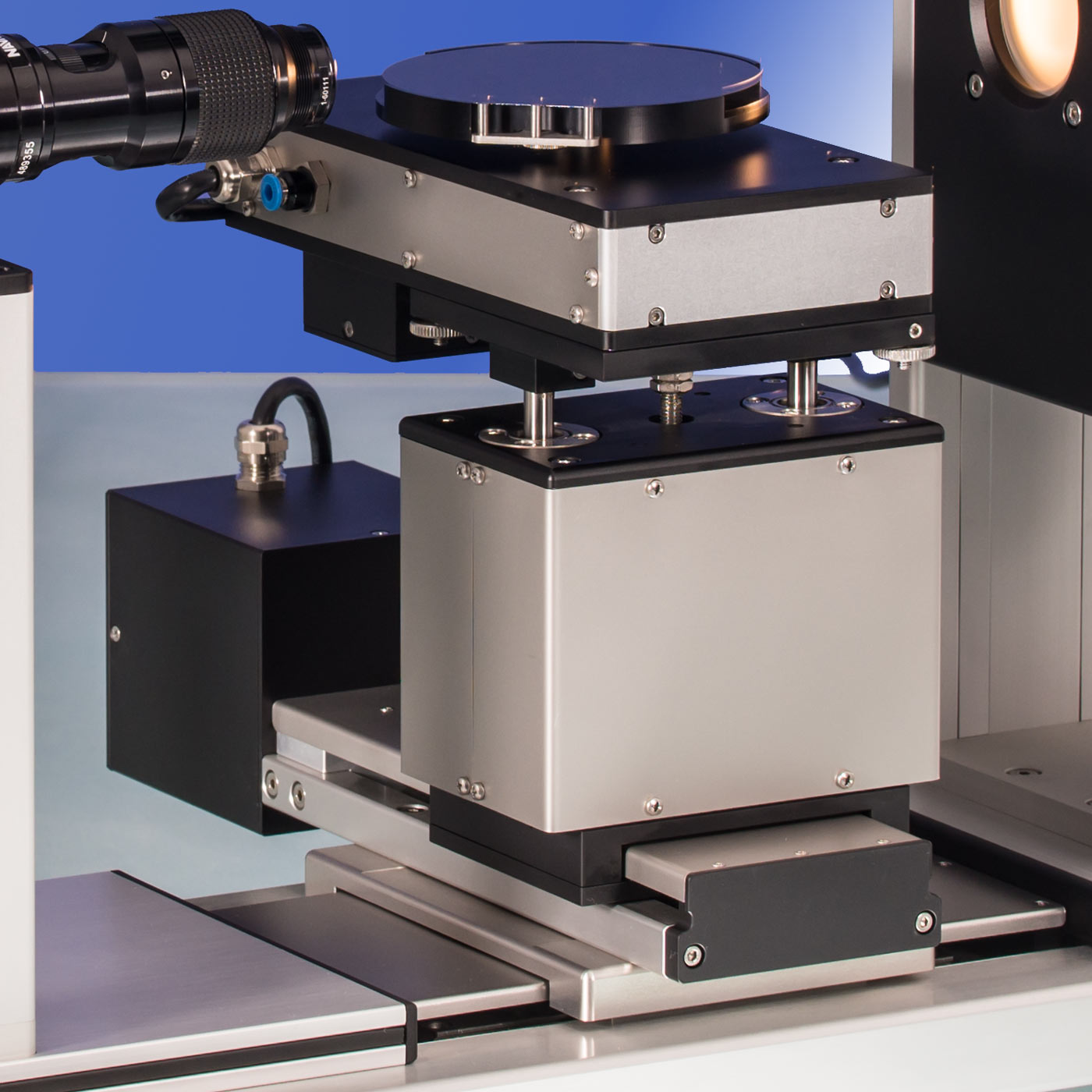

OCA

50

OCA 50

The OCA 50 is the fully automatic measuring device for the time-saving analysis of the wettability of solid surfaces and the determination of the surface energy of solids.

The sample table of the OCA 50 can be positioned along all three directions in space via electronic high-performance axes, with both extraordinary speed and highest precision.

Combined with an electronic multiple direct dosing system DDE/x and up to four electronic syringe modules ESr-N the determination of surface parameters can be automated completely.

The automation of measurements succeeds easier than ever before thanks to the intuitive automation dialogue of the SCA software and its visual drop positioning system. Hence it is possible to determine, for example, the surface energy with four test liquids at different position of even large samples without any manual user intervention. This facilitates a complete and automated sample mapping.

In order to map silicon wafers, electronic turn tables with vacuum fixation are available. They allow to access any position for contact angle measurements, even on 12 wafers.

In any case, the 6-fold zoom lens and the high-performance camera with USB 3.0 interface ensure optimal images of the deposited drops.

For a fast and intuitive device control, even during complex measurements, the TP 50 control panel with touch screen and precision control wheel is included with every OCA 50.

|

|

|

|

Main features:

|

|

|

sample table adjustable in all three directions in space with electronic high-performance axes

|

|

|

|

|

high performance 6-times zoom lens

|

|

|

|

|

integrated continuous fine focus,

and adjustable observation angle

|

|

|

|

|

video measuring system with high-performance camera using USB 3.0 interface

|

|

|

|

|

LED-lighting with manual and software controlled intensity including automatic temperature drift compensation

|

|

|

|

|

included TP 50 control panel with touch screen and precision control wheel

|

|

Software:

|

|

|

SCA 20 - contact angle

|

|

|

|

|

SCA 21 - surface energy

|

|

|

|

|

SCA 22 - surface and interfacial tension

|

|

|

|

|

SCA 23 - liquid bridge analysis

|

|

|

SCA 26 - oscillation / relaxation

|

|

|

SCA 27 - topview contact angle

|

|

|

|

|

| |

|

|

|

| |

|

|

|

|

|

|

|

|

OCA 200

The OCA 200 is the contact angle measuring and drop contour analysis system for microscopic and macroscopic structures.

The software-controlled, electrically driven optic alignment enables the OCA 200 to adjust the observation angle and to focus automatically.

With the trendsetting 10-fold zoom lens and the reliable auto focus system by DataPhysics Instruments, the OCA 200 is equipped to handle any kind of sample size from a macroscopic silicon wafer to the microscopic mesh structure of a coronary stent.

In combination with the high-performance camera with USB 3.0 interface even smallest drops of highly volatile liquids can be monitored.

The electrically driven sample table makes it possible to position micro-structured samples with highest precision and exceptional speed for fast automated measuring procedures.

With an electronic multiple direct dosing system DDE/x and up to four electronic syringe modules ESr-N liquids can be deposited on a macroscopic sample and its surface parameters can be determined automatically.

For the analysis of micro-structured samples the nanolitre dosing system is available which can generate down to 10 nanolitre small droplets. These droplets are small enough to fit, for example, between the screw threads of a dental implant whose surface is to be analysed.

Even smaller structures can be analysed using the picolitre dosing system PDDS which can dose down to 30 picolitre small droplets. These allow contact angle measurement, for example, on the individual wires of the mesh structure of a coronary stent or on single fibres.

|

|

|

|

Main features:

|

|

|

sample table adjustable in all three directions in space with electronic high-performance axes

|

|

|

|

|

trendsetting 10-fold zoom lens

|

|

|

|

|

software-controlled, electrically driven optic alignment for autofocus and adjustment of the observation angle

|

|

|

|

|

video measuring system with high-performance camera using USB 3.0 interface

|

|

|

|

|

LED-lighting with manual and software controlled intensity including automatic temperature drift compensation

|

|

|

|

|

included TP 50 control panel with touch screen and precision control wheel

|

|

|

|

|

SCA 20 - contact angle

|

|

|

|

|

SCA 21 - surface energy

|

|

|

|

|

SCA 22 - surface and interfacial tension

|

|

|

|

|

SCA 23 - liquid bridge analysis

|

|

|

SCA 26 - oscillation / relaxation

|

|

|

SCA 27 - topview contact angle

|

|

|

|

|

| |

|

|

|

| |

|

|

|

|

|

|

|

|

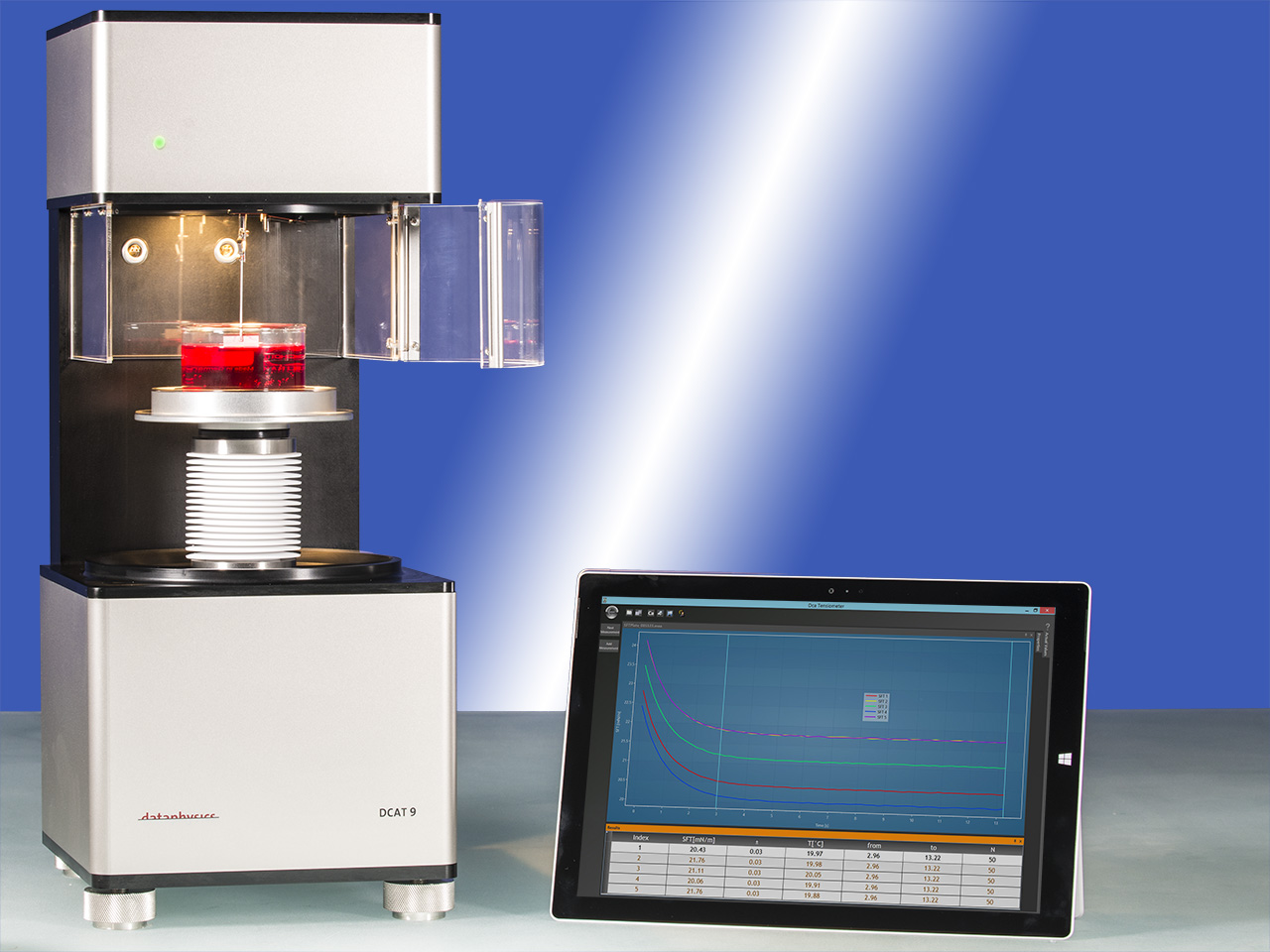

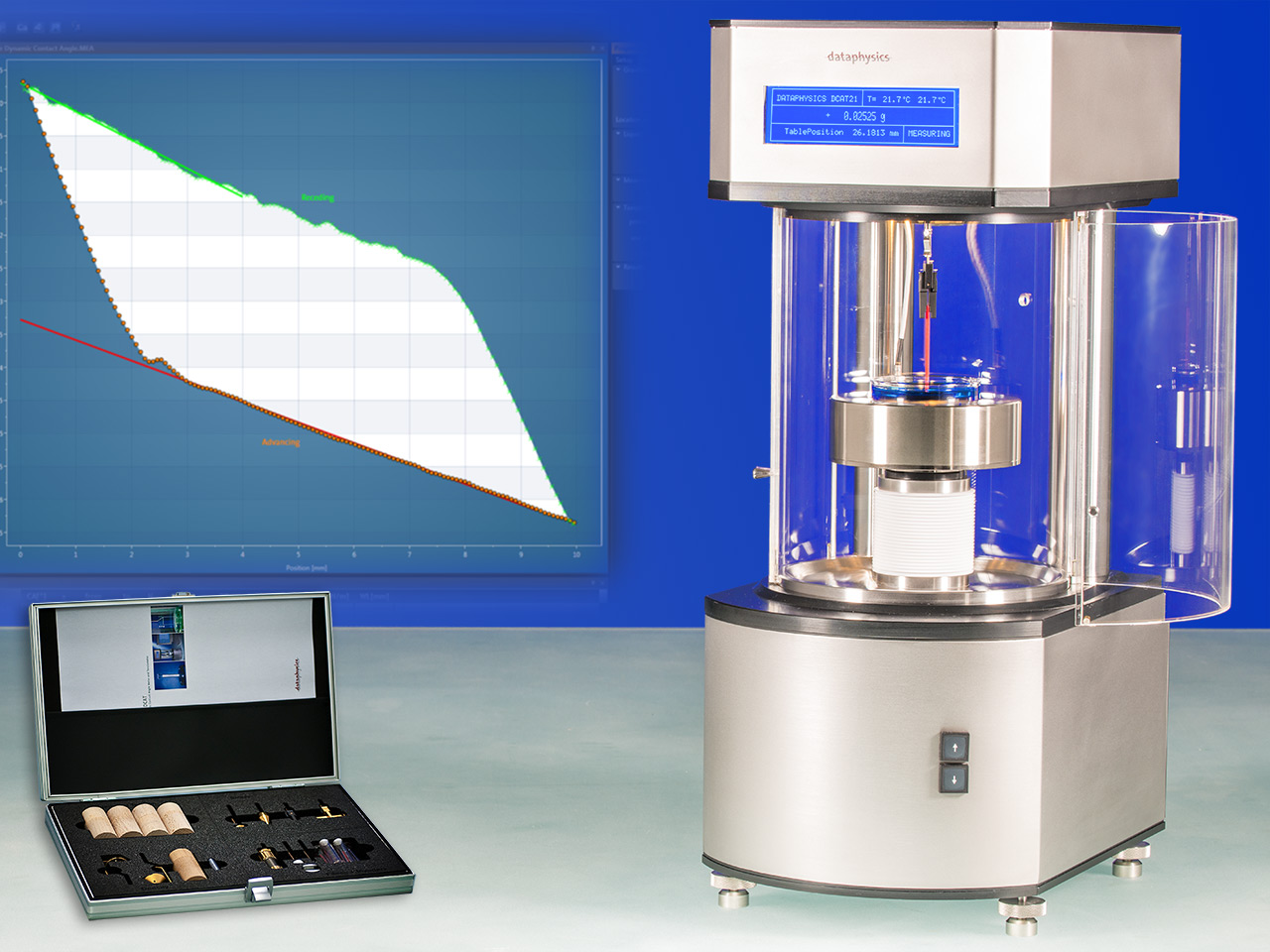

DCAT 9 & DCAT 9T

The DCAT 9 is the powerful entry level model for the weight-based measurement of surface and interfacial tension and the density of liquids and solids. In order to measure temperature dependent properties the DCAT 9T features an integrated digital thermometer and a liquid temperature control unit TV 70.

|

|

Main features:

|

|

|

|

|

electrodynamic compensation weighing system with automatic and manual calibration function

|

|

|

|

|

software controlled, motor-driven height positioning of the sample receptacles with variable speed

|

|

|

|

|

automatic coupling lock for the balance

|

|

|

|

|

automatic crash protection for measuring probes during measurement

|

|

|

|

|

illuminated sample chamber

|

|

|

|

|

integrated magnetic stirrer

|

|

|

|

|

standard sample vessel holder SVH

50/70 (DCAT 9)

|

|

|

|

|

digital thermometer with connections for two Pt100 temperature sensors (DCAT 9T)

|

|

|

|

|

liquid temperature control unit TV 70 with Pt100 probe (DCAT 9T)

|

|

Software:

|

|

|

DCATS 31 - surface and interfacial tension

|

|

|

|

|

DCATS 34 - liquid density

|

|

|

DCATS 36 - solid density

|

|

|

|

|

| |

|

|

|

| |

|

|

|

|

|

|

|

|

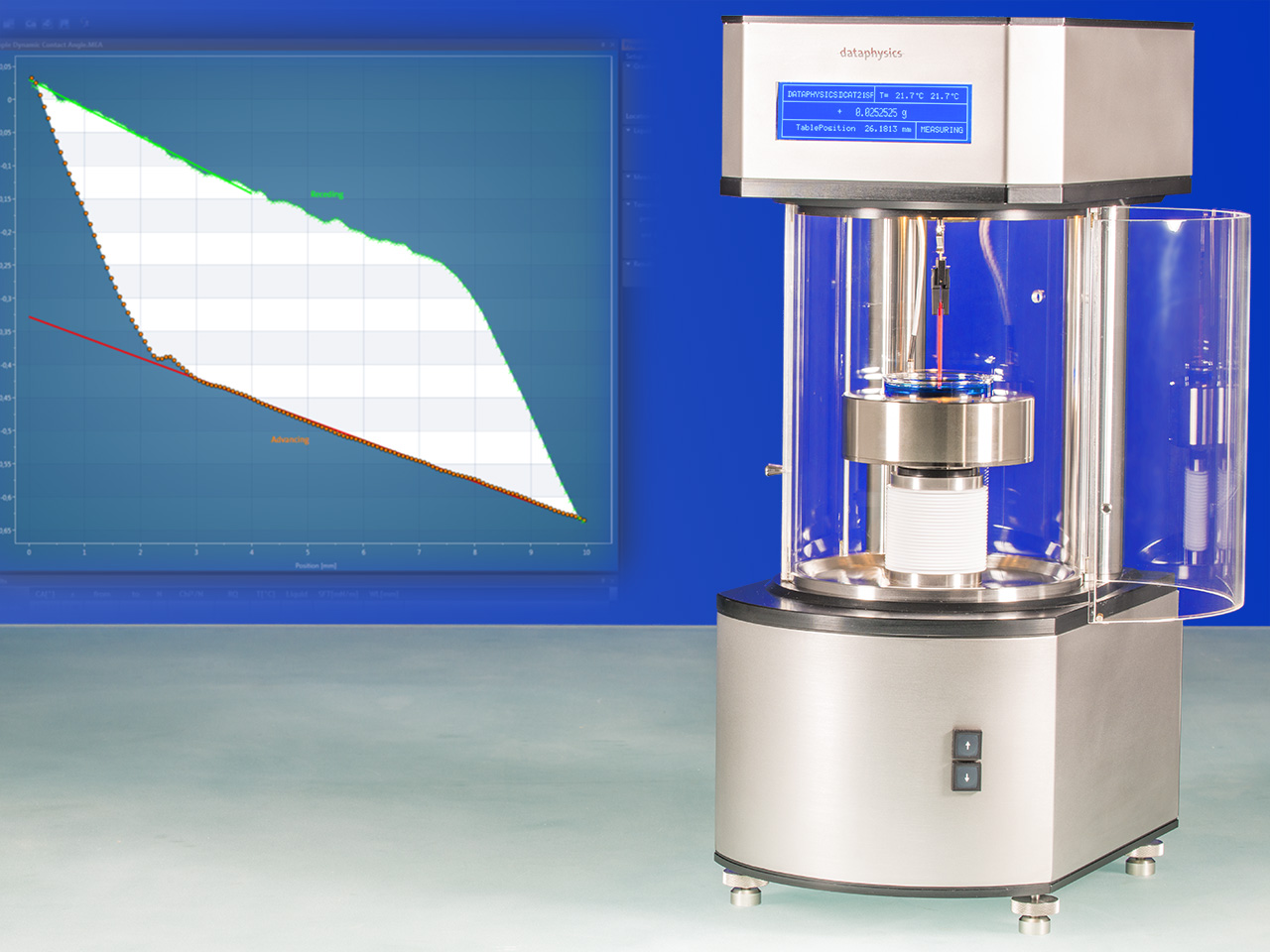

DCAT15

The DCAT 15 enables additional measuring methods and hence can be used to determine dynamic contact angles, the surface energy of solids or sedimentation and penetration properties. In addition the DCAT 15 can be extended with a liquid dosing unit LDU 25 and can thus create sequential concentration series of, for example, surfactant solutions. Without manual user intervention the critical micelle concentration (CMC) can be determined software controlled in a series of experiments.

|

|

|

|

Main features:

|

|

|

electrodynamic compensation weighing system with automatic and manual calibration function

|

|

|

|

|

software controlled, motor-driven height positioning of the sample

|

|

|

|

|

automatic coupling lock for the

balance automatic crash protection for measuring probes during

measurement

|

|

|

|

|

illuminated

sample chamber

|

|

|

|

|

integrated

magnetic stirre

|

|

|

|

|

digital

thermometer with connections for two Pt100 temperature sensors

|

|

|

|

|

compatible with the liquid dosing unit LDU 25

|

|

|

|

|

automatic crash protection for measuring probes during measurement

|

|

Software:

|

|

|

DCATS 31 - surface and interfacial tension

|

|

|

|

|

DCATS 34 - liquid density

|

|

|

|

|

DCATS 35 - sedimentation and penetration

|

|

|

|

|

DCATS 36 - solid density

|

|

|

|

|

| |

|

|

|

| |

|

|

|

|

|

|

|

|

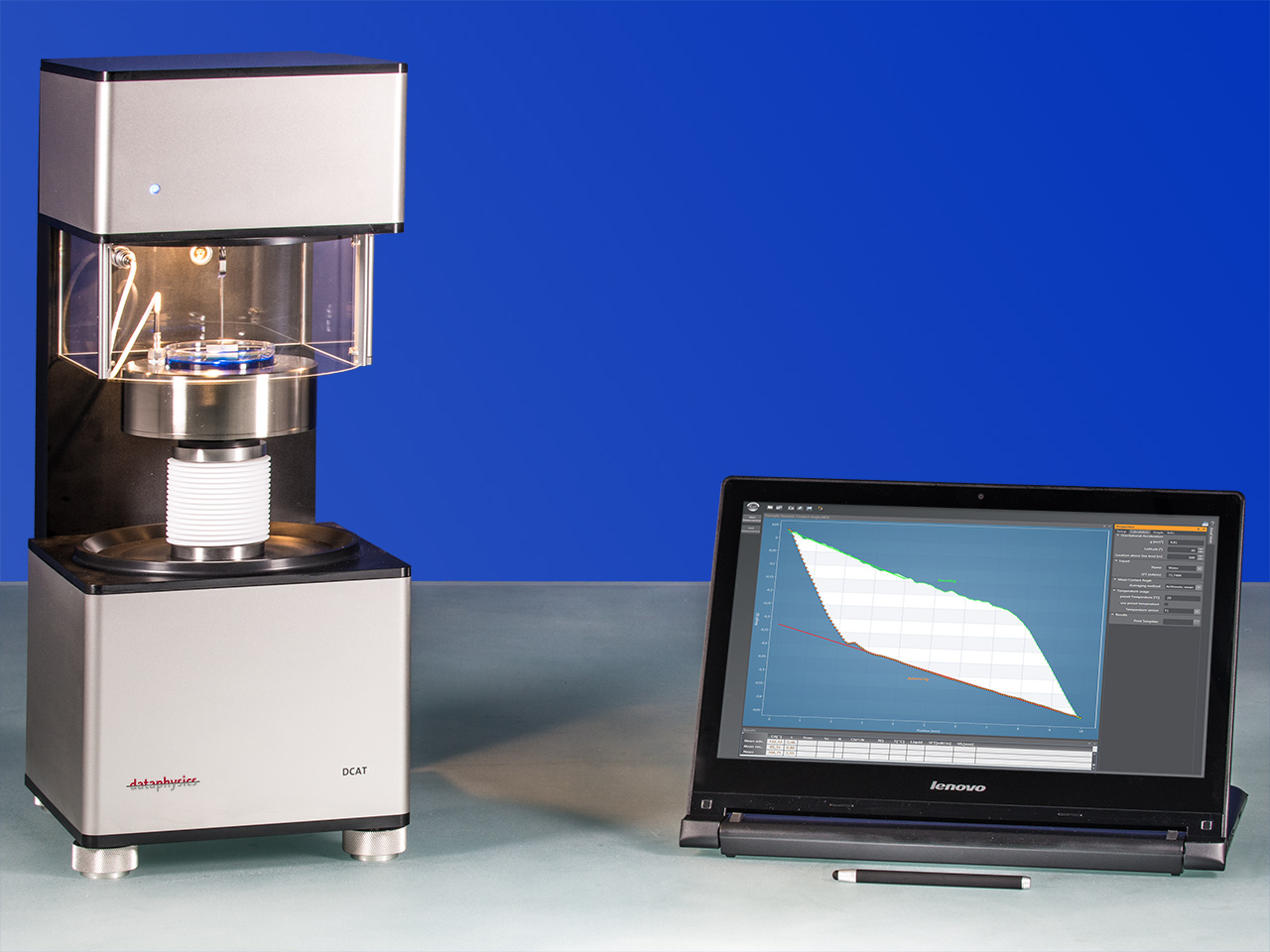

DCAT

25

The dynamic contact angle measuring device and tensiometer DCAT 25 is the multifunctional all-round instrument of the DCAT series. The weighing system is even more precise than that of the DCAT 9 and 15 and hence offers highest accuracy for the determination of surface and interfacial tension. A completely closed sample chamber enables measurements under inert gas or ionised atmosphere as well as with controlled relative humidity.

Due to the longer travel distance of the sample stage, an electrical temperature control unit can be mounted inside the DCAT 25 which makes measurements at temperatures of up to 250C possible. Moreover the Langmuir trough module can be used to investigate the surface pressure and the interfacial rheology of monolayers. The upgrade video system provides the opportunity to record video-sequences during force of adhesion measurements and to evaluate contact angle, contact area etc. in addition to the force. For an intuitive and fast device control even during complex measurements, a TP 50 control panel is included in the delivery of every DCAT 25.

|

|

|

|

Main features:

|

|

|

high resolution electrodynamic compensation weighing system with automatic and manual calibration function

|

|

|

|

|

software controlled, motor-driven height positioning of the sample receptacles with variable speed

|

|

|

|

|

automatic coupling lock for the balance

|

|

|

|

|

|

|

automatic crash protection for measuring probes during measurement

|

|

|

|

|

closed illuminated sample chamber

|

|

|

|

|

|

|

integrated magnetic stirrer

|

|

|

|

|

|

|

digital thermometer with connections for two Pt100 temperature sensors

|

|

|

|

|

|

|

includes a TP 50 control panel with touch screen and precision control wheel

|

|

|

|

|

|

|

compatible with the liquid dosing unit LDU 25

|

|

|

|

|

|

|

compatible with the electrical temperature control unit TEC 250/DCAT

|

|

|

|

|

|

|

compatible with the upgrade video system UpVideo DCAT

|

|

|

|

|

|

|

compatible with the Langmuir trough module LTM

|

|

|

|

Software:

|

|

|

DCATS 31 - surface and interfacial tension

|

|

|

|

|

DCATS 32 - dynamic contact angle

|

|

|

|

|

DCATS 33 - critical micelle concentration (CMC)

|

|

|

|

|

DCATS 34 - liquid density

|

|

|

|

|

DCATS 35 - sedimentation and penetration

|

|

|

|

|

DCATS 36 - olid density

|

|

|

|

|

DCATS 37 - adhesion

|

|

|

|

|

DCATS 38 - surface pressure

|

|

|

| |

|

|

|

| |

|

|

|

|

|

|

|

|

DCAT25

SF

The DCAT 25SF incorporates a weighing system of highest accuracy with a resolution of 0.1 ug which allows to measure even on single fibres. As an ideal single fibre tensiometer the DCAT 25SF is not limited to this very special purpose due to the modular design of the product line.

|

|

|

|

Main features:

|

|

|

electrodynamic compensation weighing system of highest resolution with automatic and manual calibration function

|

|

|

|

|

software controlled, motor-driven height positioning of the sample receptacles with variable speed

|

|

|

|

|

automatic coupling lock for the balance

|

|

|

|

|

automatic crash protection for measuring probes during measurement

|

|

|

|

|

closed illuminated sample chamber

|

|

|

|

|

digital thermometer with connections for two Pt100 temperature sensors

|

|

|

|

|

digital thermometer with connections for two Pt100 temperature sensors

|

|

|

|

|

includes a TP 50 control panel with touch screen and precision control wheel

|

|

|

|

|

compatible with the Langmuir trough module LTM

|

|

|

|

Software:

|

|

|

DCATS 31 - surface and interfacial tension

|

|

|

|

|

DCATS 32 - dynamic contact angle

|

|

|

|

|

DCATS 33 - critical micelle concentration (CMC)

|

|

|

|

|

DCATS 34 - liquid density

|

|

|

|

|

DCATS 38 - surface pressure

|

|

|

| |

|

|

|

| |

|

|

|

|

|

| |

|

PCA

100M

Whether it be for large or small substrate areas, the PCA 100M is the

ideal, handheld, portable instrument for controlling the qualities of

coatings, examining the surface energies of pre-treated polymer films

in the production process, or testing the qualities of cleaned or

adhesion promoted glass surfaces, prior to the next processing stage.

The compact design and the plug and play connectivity, to any

notebook or on-site available PC, without the need for a special frame

grabber, enables the measurement of surface properties almost

everywhere ? including use in cleanrooms (US FED STD 209E cleanroom

standard class 10).

|

|

|

|

Features of the basic

instrument configuration:

|

|

|

High-performance

telecentric lens with integrated aperture and adjustable observation

angle.

|

|

|

|

|

Video

measuring system (max. 50 images/s sample rate). Software controlled

continually adjustable back lighting, without hysteresis.

|

|

|

|

|

Integrated multiple dosing

system, with either two dosing needles (PCA 100M/2) or four dosing

needles (PCA 100M/4), for software controlled automatic needle

selection and positioning.

|

|

|

|

|

Integrated

automatic refill system with flushing and cleaning functions for dosing

up to 5000 drops per filling and per liquid receptacle.

|

|

|

|

|

Power

supply with automatic voltage adjustment.

|

|

|

|

|

| |

|

|

|

| |

|

|

|

|

|

|

|

|

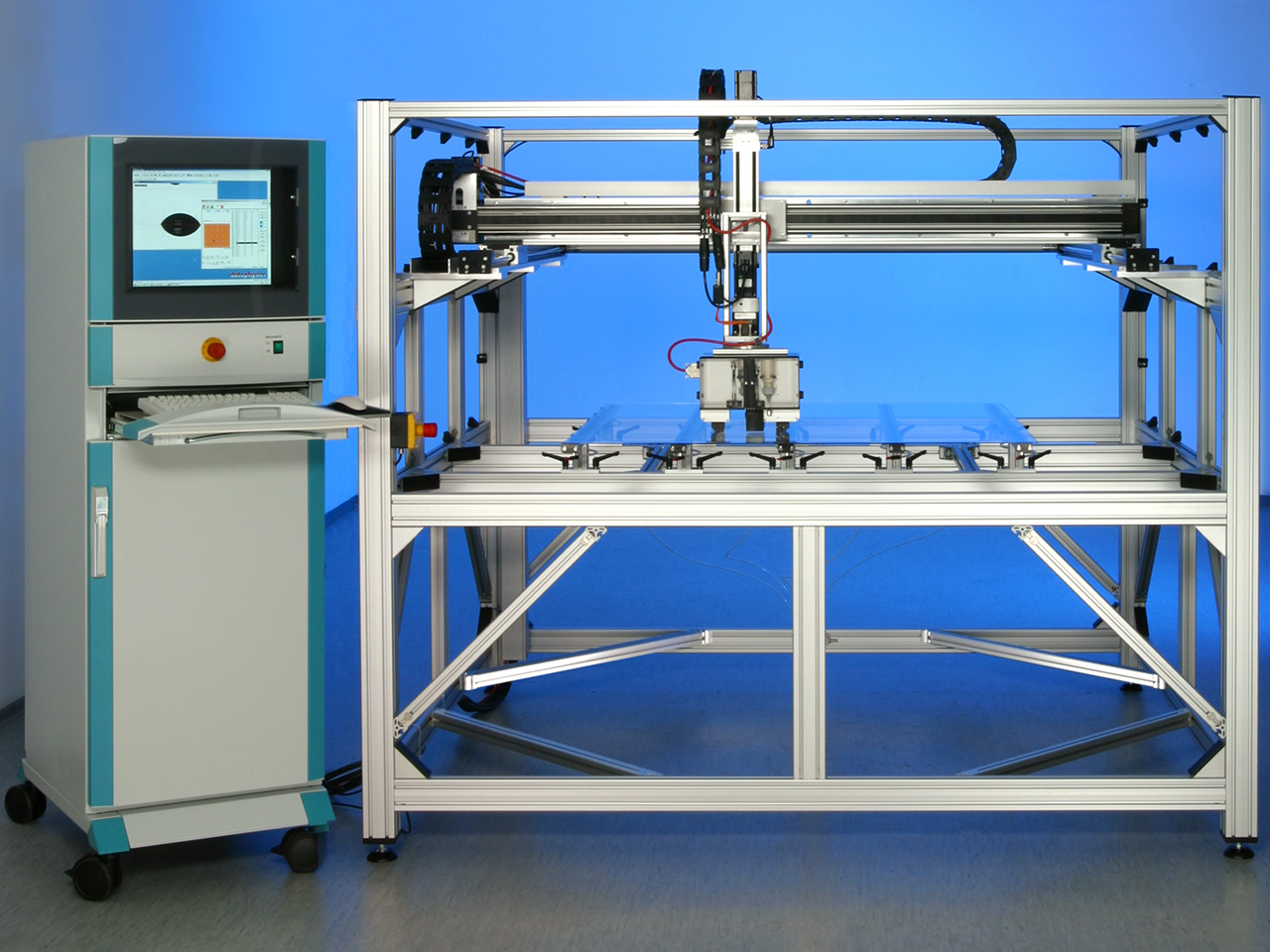

Robotically

guided contact angle measuring instrument for process control.

In combination with the single and multi axis cartesian robots of the

RCC series, the PCA 100R contact angle measuring instrument is a

specialised system for measuring wetting properties on substrates of

very large surface areas, on site, during the production process. The

fully automatic instrument enables the removes operator variability and

other subjective factors and of the time necessary for the contact

angle measurement.

|

|

|

|

Some important

applications for the robotically guided PCA 100R are:

|

|

|

determination

of the surface cleanliness of wafers and glass substrates for flat

screens before the next manufacturing step.

|

|

|

|

|

examining

the surface energies of pre-treated polymer films in the production

process.

|

|

|

|

|

development of high-performance

composites.

|

|

|

|

|

surface

finishing and the cleaning of textiles. The PCA 100R and the robots of

the RCC series are designed for the usage in cleanrooms according the

US FED STD 209E cleanroom standard class 10.

|

|

|

|

Features of the basic

instrument configuration:

|

|

|

|

|

|

|

|

|

measuring

head with integrated optics, illumination and multiple dosing unit.

|

|

|

|

|

|

|

high-performance

telecentric lens with integrated aperture and adjustable observation

angle.

|

|

|

|

|

|

|

video-based

measuring system with high-resolution CCD camera and high-performance

digitizing adapter.

|

|

|

|

|

|

|

software

controlled continuous adjustable intensity without hysteresis for a

homogeneous back lighting.

|

|

|

|

|

|

|

automatic

needle selection and positioning.

|

|

|

| |

|

|

|

| |

|

|

|

|

|

|

|

|

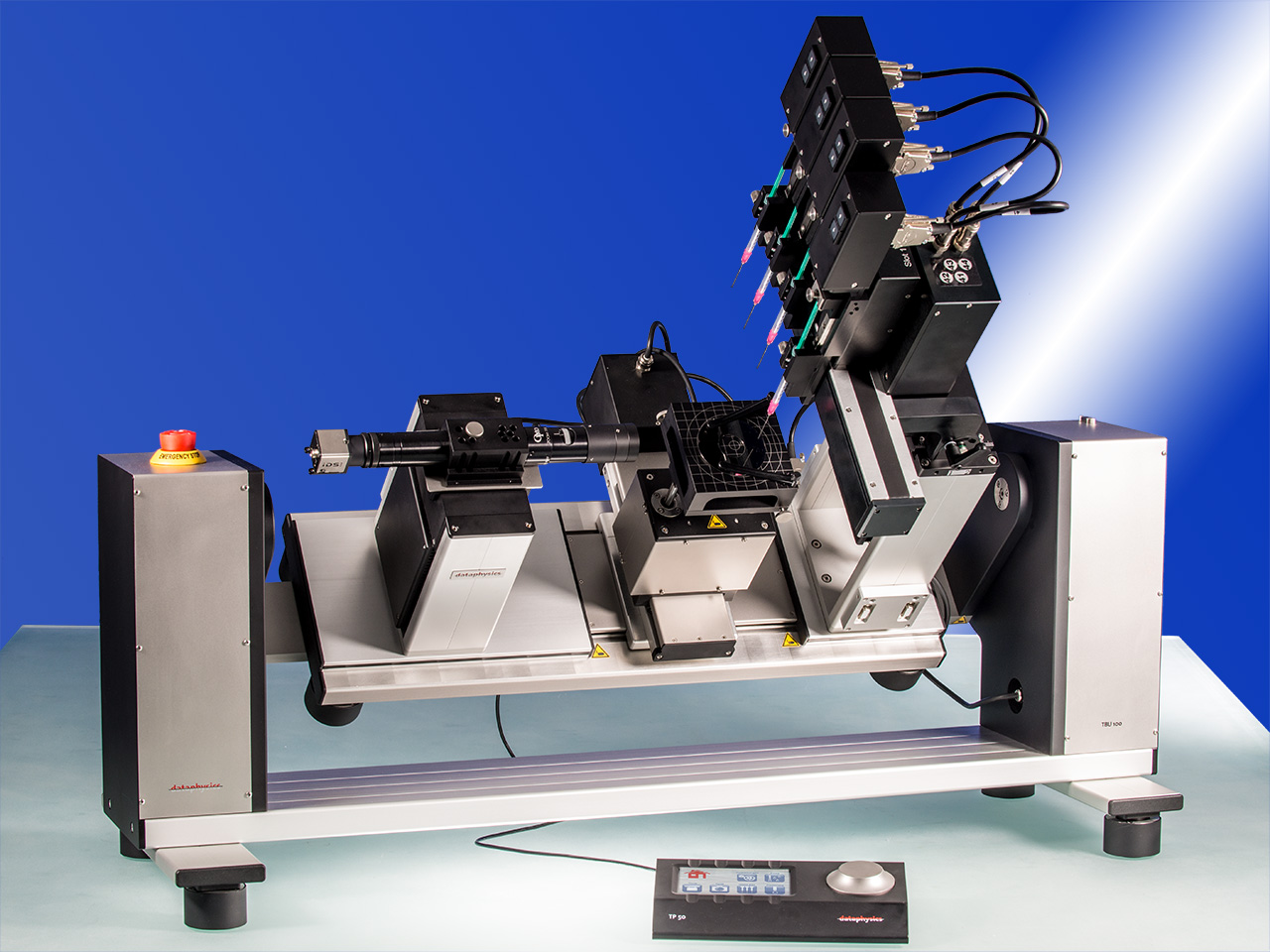

SVT 15N

The Spinning drop video tensiometer SVT 25 is a compact optical measuring instrument for the determination of low to ultra-low interfacial tensions and rheological interface properties. Highest precision and reproducibility of the measuring results is guaranteed by a well-established measuring technique and first grade mechanical and optical components. Due to state of the art electronic components the SVT 25 can be operated intuitively via the TP 50 control panel.

|

|

Main features:

|

|

|

|

|

Measurement of low to ultra-low interfacial tensions based on the contour of spinning drops according to models by Vonnegut, Cayias-Schechter-Wade or Young-Laplace

|

|

|

highly dynamic measurement drive with 0 ~ 20000 rev/min

|

|

|

|

|

oscillation measurements with oscillation periods of 0.5 s and max. acceleration of 500 rev/s2

|

|

|

|

|

fast 6.5-fold zoom lens with integrated continuous fine focus

|

|

|

motorised movable optics for automatically following moving drops

|

|

|

high-performance camera with USB 3 interface, 2/3 sensor, max. 2048 x 1088 pixel, max. 3250 frames/s

|

|

|

temperature controlled measuring cells for temperatures ranging from -30 to 180

|

|

Software:

|

|

|

SVTS 20 interfacial tension

SVTS 21 oscillation

SVTS 22 membrane covered drops

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

| |

|

|

|

|

|

|

|

|

HGC

20

The humidity generator HGC 20 is designed for the automated regulation

of the relative humidity of ambient clean air for a wide range of

applications.

|

|

|

|

Features of the basic

instrument configuration:

|

|

|

It

is easily connectable to many environmental chambers of DataPhysics and

other suppliers.The ambient air first flows through the integrated

desiccant reservoir. An electronic valve, controlled by the humidity

and temperature sensor directly mounted in the measuring chamber

diverts some air through the heated water reservoir before it flows

through the heated connection tube.

|

|

|

|

|

Stand

alone generation of dry air without an external pressurized gas supply

|

|

|

|

|

Heated water reservoir Heated

connection gas tube (transfer line) to thermal chamber to avoid

condensation

|

|

|

|

|

Easy

control via touch-screen or optional software Serial RS 485 or USB

interface Calculation of dew point in the measuring chamber

|

|

|

|

|

Automated

drying and regeneration of desiccant by a built-in heating system in

two alternatively used desiccant reservoirs (total stored desiccant

amount about 1.0 kg).

|

|

|

|

|

|

|

| |

|

|

|

| |

|

|

|

|

|

|

|

|

HGC

30

The humidity generator HGC 30 is designed for the automated regulation

of the relative humidity of ambient clean air for a wide range of

applications. It is easily connectable to many environmental chambers

of DataPhysics and other suppliers. The ambient air or the external

supplied gas first flows through the integrated desiccant reservoir. An

electronic valve, controlled by the humidity and temperature sensor

directly mounted in the measuring chamber diverts some air through the

heated water reservoir before it flows through the heated connection

tube.

|

|

|

|

Features of the basic

instrument configuration:

|

|

|

Stand

alone generation of dry air/gas with and without an external

pressurized gas supply.

|

|

|

|

|

Heated

water reservoir Heated connection gas tube (transfer line) to thermal

chamber to avoid condensation

|

|

|

|

|

Easy control via touch-screen or

optional software Serial RS 485 or USB interface Calculation of dew

point in the measuring chamber

|

|

|

|

|

Automated

drying and regeneration of desiccant by a built-in heating system in

two alternatively used desiccant reservoirs (total stored desiccant

amount about 1.0 kg).

|

|

|

|

|

Additional

external gas supply with integrated pressure regulator Integrated flow

rate controller (calibrated for N2 and Ar).

|

|

|

|

|

|

|

| |

|

|

|

| |

|

|

|

|

|

|

|

|

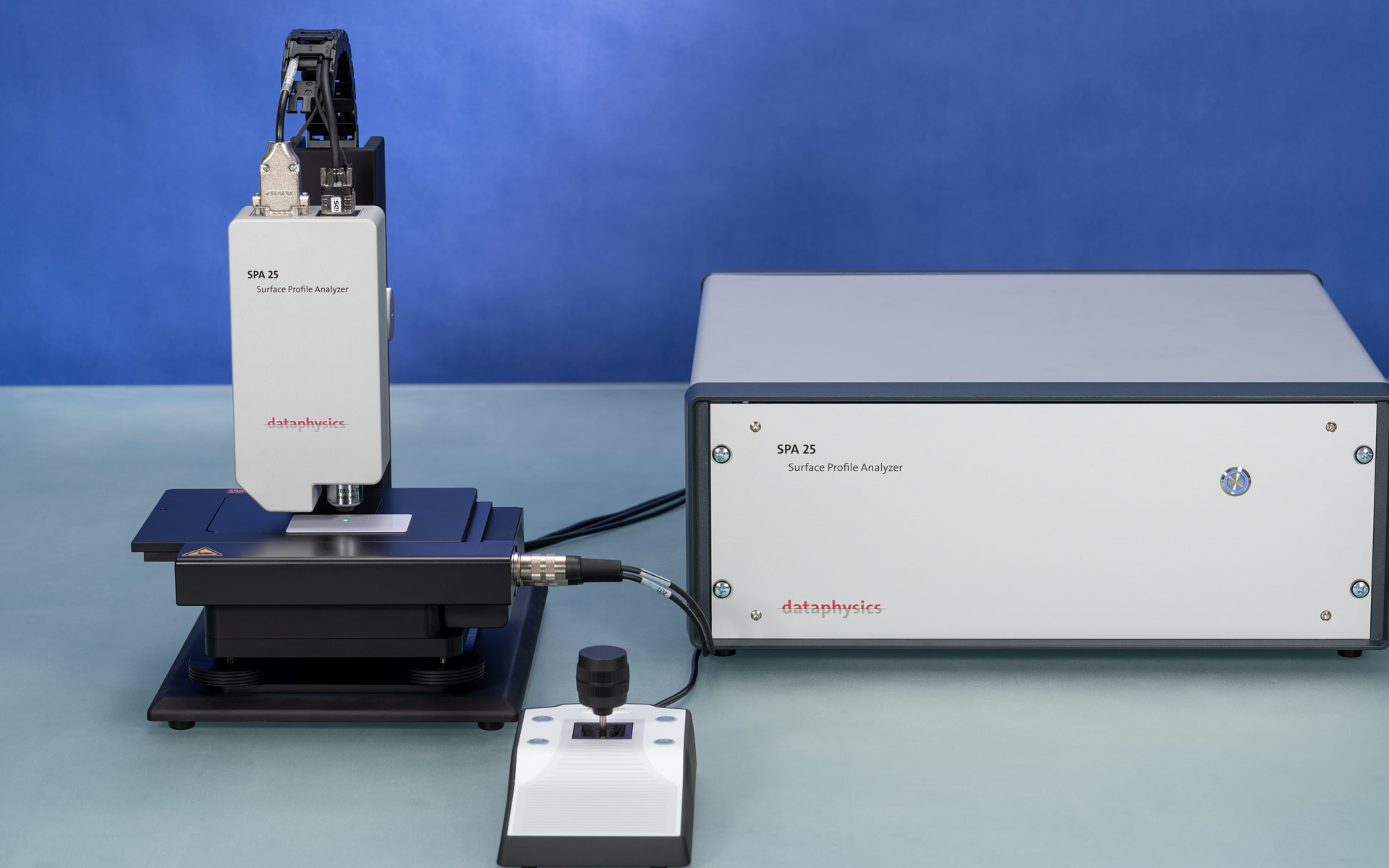

SPA

The Surface Profile Analyzer SPA 25 can measure surface topography and roughness parameters with exceptional speed and resolution. In the following you will learn about the possibilites that surface profile analysis offers and how the white-light interferometry enables the SPA 25 to achieve a height resolution of down to 0.1 nm.

Surface Profile Analysis

Utilising the industry leading MountainsMap Imaging Topography software provides a comprehensive set of tools for the analysis of the studied surface.

The SPA 25 can be used to create 3D maps of large surface areas (up to 300 mm x 300 mm with automated sample table) and e.g. detect defects caused by material processing and treatment or the surface roughness can be analysed according to various industry standards like ISO 25178, ISO 4287, ISO 13565, ISO 16610, etc.

Using the SPA 25 in combination with an optical contact angle measuring and contour analysis system of the OCA series provieds further insight into surface properties by e.g. determining the surface corrected contact angle according to the Wenzel theory.

With its high resolution even the small particle deposits created by dosing individual picoliter sized ink droplets with a DataPhysics Instruments picoliter dosing system PDDS can be analysed.

White-light interferometry

The Surface Profile Analyzer SPA 25 utilises the white-light interferometry for studying the surface topography. White-light interferometry is an optical measuring technique and due to the relatively large distance between measuring instrument and test surface there is no danger of damaging the sample compared to profiling systems that rely on some sort of stylus.

The SPA 25 uses Mirau objectives which contain abeam splitter and reference mirror within the light pathway. The lightreflected from the sample surface and the light reflected within the objectiveitself create an interference image. The interference pattern has its highestcontrast when the sample is exactly in the focus plane of the objective andbecomes less intense closer/further away from the focus plane.

When the distance between sample and Mirau objectiveis changed the interference pattern changes correspondingly. The SPA 25changes the distance between sample surface and the objective with apiezoelectric precision scan drive. By sampling various distances and analysingthe changing interference pattern the height of every point in the frame can becalculated.

The increased amount of available parallel computationpower provided by modern graphics cards enables highly sophisticated evaluationalgorithms. Hence the SPA 25 can process up to 500 GByte of image datawith each scan and provide a height resolution of down to 0.1 nm usingthe extended phase shift interferometry (EPSI) scan mode.

A significant advantage of white-light interferometrycompared to other optical height resolving methods like focus variation orconfocal microscopy is that the height (Z-direction) resolution is independentof the magnification factor of the used objective. The magnification factoronly changes the lateral (X-Y-direction) resolution.

|

|

|

|

Main features

|

|

|

white-light interferometry measurementtechnique

|

|

|

|

|

precision piezoelectric scan drivewith gauge control

|

|

|

|

|

up to 400 μm scan range(z-direction) and 11.3 μm/s scan speed at full resolution

|

|

|

|

|

USB 3 high speed camera with 1920 x1200 pixel max. resolution and up to 3000 frames/s with restricted ROI

|

|

|

|

|

two scan modes:

VSI (vertical scanning interferometry)with 1 nm height resolution

EPSI (extended phase shiftinterferometry) with 0.1 nm height resolution

|

|

|

Mirauinterferometermicroscope objectives with different magnificationfactors

|

|

|

manual or automaticsample table

|

|

|

control unit with integrated powerfulPC

|

|

Software

The SPA25 is controlledvia the SPS 25 Surface Profile Software. It uses the industry leadingMountainsMap® Imaging Topography evaluation software to analyse the surfaceprofile.

|

|

|

|

|

|

|

| |

|

|

|

|

|

|